This specification covers polyester overcoated with polyamide or polyester imide enameled copper wire, class 180 to be used in winding and wiring of transformer, motor,generator and so on. (Hereinafter referred to as wire)

Polyester overcoated with polyamide or polyester imide enameled round copper wire(QZY-2/180 0.250mm Enameled Copper Wire): class 180

3.1 Conductor

The conductor shall be transformed into annealed copper wire.

3.2 Insulating Film

Baking Polyester overcoated with polyamide or polyester imide insulating varnish shall make the insulating film of the wire Class 180 on the conductor uniformly and perfectly

The characteristics of wire shall comply with table 2, when tested by 5.0.

| Item | Characteristics | Test Method |

| Appearance | No flaws. Smooth surface and uniform color. Not Sticky | 5.1 |

| Dimensions | To comply with IEC requirements. | 5.2 |

| Pin hole | 3 holes/1m Max. | 5.3 |

| Flexibility | Film free from cracks such as to expose the conduct. | 5.4 |

| Adherence | Film free from cracks such as to expose the conduct. | 5.5 |

| Broken-down voltage | 1700 V(Min) | 5.6 |

| Resistance to solvent | No bubble or blister in film | 5.7 |

| Heat shock | Film free from cracks such as to expose the conduct | 5.8 |

| Conductor resistance | To comply with IEC requirements | 5.9 |

| Elongation | 20%(Min) | 5.10 |

5.1 Appearance

The appearance shall be examined, as wound on bobbin, for existence of flaw and stain; by naked eye to determine its appearance.

5.2 Dimensions. The dimensions shall be measured by using of a micrometer.

5.3 Pinhole. The pinhole test by the 12 volts DC,one minutes.

5.4 Flexibility: The springiness at room temperature test

5.5 Adherence The adherence test

5.6 Broken-down voltage The broken-down voltage test

5.7 Resistance to Solvent The resistance to solvent test

5.8 Heat Shock. The heat shock test, the thermostatic box kept in advance at 240±5℃ Min.

5.9 Conductor Resistance The electrical resistance test

5.10 Elongation. The elongation test

The inspection shall be carried out using the test methods 5, on the items specified from 3, 4. If the purchaser and the supplies have an agreement, some items can be omitted.

(1)Appearance

(2)Dimensions

(3)Flexibility

(4)Adherence

(5)Broken-down voltage

(6)Resistance to Solvent

(7)Heat shock

(8)Electrical Resistance

(9)Elongation

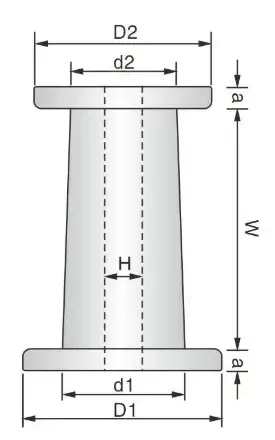

| Spool Type | MEASUREMENT | |||||

| d1 | d2 | D1 | D2 | H1 | H2 | |

| PT-30 | 22.2 | 110 | 24.7 | 130 | 24.5 | 28.5 |

| PT-60 | 269 | 150 | 296 | 178 | 350 | 400 |

| Spool Type | MEASUREMENT | |||||

| d1 | d2 | D1 | D2 | H1 | H2 | |

| PT-90 PCZ-315 | 300 | 180 | 315 | 200 | 425 | 500 |

| PT-200 PCZ-400 | 375 | 225 | 400 | 250 | 530 | 630 |

| PT-270 | 435 | 225 | 460 | 280 | 528 | 628 |

The wire shall be designated by class and conductor dimension or by symbol and conductor dimensions. Example Enameled Round copper wire, temperature Class 180℃, 0.15mm

The spool and container shall be marked at a specified place with the following items: (1)Designation; (2 Dimensions; (3)Manufacturing Lot number;(4)Net weight; (5)Manufacturer.

1) Attention in handling

*Please note use in the place where the ignition source by the fire, static electricity, and the impact spark, etc. is caused enough.

*Please avoid contact with the medicines such as a strong acid, strong alkali, and organic solvents. *Please wear protective glasses at the coil winding.

*The harmful gas is generated from the insulation film when removing the insulation film by heat or solder. Please use the exhaust equipment, and do not inhale directly.

*Please follow the instruction concerning handling, when you use the medicines for removing. *Please do not roll bobbin to generate loosening and the tangle of the wire.

* There is a possibility of causing a minute crack on the insulation film when touching it to moisture, water, the solvent, and the medicine, while suffering stress to the insulation film. Therefore, we recommend heat-treating it after the coil is built or before the varnish is processed.

*Please note handling when you move the wire, and do not treat the product by the hand that attaches the moist hand and the hand cream.

2 )Attention in keeping

*Please store it in a room, avoid it being under the high temperature and humidity environment or exposed directly to the sunshine.

*Please mind the pile height.

3)Storage:

Storage temperature: 5~35℃

Relative humidity: 85% or less (Do not generate the dewy on the surface of the wire.)

4) Attention in Recycle

Please recycle if it is possible because copper is main material in this product. When recycling is impossible, please process as industrial waste.

Enameled Aluminum Wire

Enameled Aluminum Wire

Enamelled Copper Wire

Enamelled Copper Wire

.jpg) Polyester or polyesterimide ov

Polyester or polyesterimide ov

Super Enameled Copper Wire

Super Enameled Copper Wire